Does a Manual Transmission Have a Torque Converter?

No, manual transmissions do not use torque converters. They utilize a clutch system to disconnect the engine from the transmission, enabling gear changes without stalling the engine.

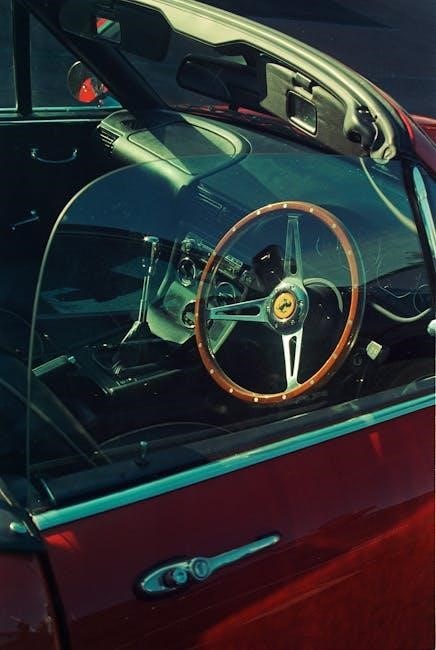

Manual and automatic transmissions are two distinct systems that transfer engine power to the wheels. Manual transmissions rely on a clutch pedal and gearshift, allowing drivers to manually select gears. Automatic transmissions, on the other hand, use a torque converter to automatically adjust gear ratios without driver input. Both systems serve the same purpose—optimizing power delivery—but differ in operation and driver involvement. Manual transmissions offer direct control, while automatics prioritize convenience and smooth power transfer. Understanding these basics helps clarify why manual transmissions do not require torque converters, unlike their automatic counterparts.

Understanding the Role of a Torque Converter

A torque converter is a hydraulic device in automatic transmissions that transfers and multiplies engine torque to the wheels. It uses fluid to connect and disconnect the engine from the transmission, allowing the engine to idle without stalling when stopped. Unlike manual transmissions, which use a clutch, the torque converter ensures smooth acceleration and seamless gear shifts. Its primary function is to optimize power delivery by adjusting the torque ratio between the engine and the transmission, enhancing performance and drivability in automatic vehicles. This fluid coupling system is a critical component for automatics but unnecessary in manuals due to their mechanical clutch systems.

Key Differences Between Manual and Automatic Transmissions

Manual and automatic transmissions differ significantly in operation and components. Manuals use a clutch pedal and gearshift for driver-controlled shifts, offering direct control and engagement. Automatics, however, rely on a torque converter to transfer power smoothly without driver input. The torque converter in automatics allows the engine to idle while the vehicle is stationary, preventing stalling. Manual transmissions lack this feature, requiring the clutch to disconnect the engine for stops. These differences impact driving experience, fuel efficiency, and maintenance needs, making each type suited for distinct preferences and driving conditions.

What Is a Torque Converter?

Definition and Purpose of a Torque Converter

A torque converter is a hydraulic device in automatic transmissions that transfers and multiplies engine power to the transmission using fluid coupling.

A torque converter is a hydraulic device in automatic transmissions that enables smooth power transfer between the engine and the transmission. It acts as a fluid coupling, allowing the engine to operate independently of the transmission while providing torque multiplication at low speeds for better acceleration. Unlike manual transmissions, which use a clutch, the torque converter automatically manages power flow, preventing engine stalling during stops and enabling seamless gear shifts. This makes it a critical component for maintaining smooth and efficient vehicle operation in automatic vehicles.

How a Torque Converter Works

A torque converter is a fluid coupling device that transfers rotating power from the engine to the transmission. It consists of three main components: the impeller (connected to the engine), the turbine (connected to the transmission), and the stator (which redirects fluid flow). When the engine turns the impeller, it circulates hydraulic fluid, which then engages the turbine, powering the transmission. The stator optimizes fluid flow, enabling torque multiplication at low speeds for smoother acceleration. As engine speed increases, the torque converter’s lock-up clutch engages, reducing slippage and improving efficiency during higher-speed operation.

Components of a Torque Converter

A torque converter consists of three key components: the impeller, turbine, and stator. The impeller, attached to the engine, spins hydraulic fluid to transfer power. The turbine, connected to the transmission, receives this fluid, engaging the gears. The stator, positioned between the impeller and turbine, redirects fluid flow to enhance torque multiplication at low speeds. Additionally, a lock-up clutch is included in modern designs to directly connect the engine and transmission at higher speeds, improving efficiency and reducing slippage. These components work together to facilitate smooth power transfer in automatic transmissions.

Manual Transmission Components

Manual transmissions include a clutch system, gear system, and shifting mechanism. These components enable driver control over power transfer, unlike automatics, which use torque converters.

The Clutch System in Manual Transmissions

The clutch system in manual transmissions is a critical component that allows the driver to disconnect the engine from the transmission. When the clutch pedal is pressed, it disengages the engine’s power, enabling smooth gear shifts without causing the vehicle to stall. Unlike automatic transmissions, which rely on torque converters for power transfer, manual transmissions use the clutch to manually control the connection between the engine and the gears. This system provides direct driver control and is essential for the operation of a manual transmission vehicle, offering precision and efficiency in power delivery.

Gear System and Shifting Mechanism

The gear system in manual transmissions consists of multiple gears that drivers engage using a shift lever and clutch pedal. Each gear ratio provides optimal power delivery for different driving conditions. The shifting mechanism involves pressing the clutch to disconnect the engine, moving the gearshift to select the desired gear, and releasing the clutch smoothly to reconnect. This manual process allows drivers to control acceleration and deceleration precisely, enhancing fuel efficiency and performance. Unlike automatic transmissions, manual systems require active driver participation, making them preferred for those who enjoy hands-on driving experiences.

Why Manual Transmissions Do Not Use Torque Converters

Manual transmissions do not use torque converters because they rely on a clutch system to disconnect and reconnect the engine to the transmission. The clutch allows drivers to manually shift gears, providing direct control over power delivery. Unlike automatic transmissions, which need a torque converter to smooth power transfer and prevent stalling, manual systems depend on driver input to modulate engine speed and torque. This design eliminates the need for a torque converter, making manual transmissions simpler, lighter, and more fuel-efficient, while also offering better driver engagement and control.

Automatic Transmission Components

Automatic transmissions include a torque converter, planetary gears, and hydraulic systems. These components work together to provide smooth, automatic gear shifting and power transfer.

Torque Converter as a Core Component

The torque converter is a vital component in automatic transmissions, acting as a fluid coupling that transfers power from the engine to the transmission. It replaces the clutch found in manual systems, enabling smooth acceleration and preventing engine stalling when the vehicle stops. Unlike manual transmissions, which require driver input to disconnect and connect power, the torque converter automatically handles this process. Comprising impeller, stator, and turbine sections, it multiplies torque at low speeds, enhancing vehicle responsiveness. This hydraulic device ensures seamless power transition, making it essential for the operation of automatic vehicles.

Planetary Gears and Hydraulic Systems

Planetary gears are a fundamental part of automatic transmissions, enabling multiple gear ratios and smooth power transfer. These gear sets consist of sun, ring, and planetary gears, providing flexibility in speed and torque adjustment. The hydraulic system, powered by transmission fluid, controls the engagement of clutches and bands to activate specific gear ratios. This system ensures seamless shifting without manual intervention, unlike manual transmissions, which rely on mechanical linkage and driver input. The combination of planetary gears and hydraulic controls allows automatic transmissions to optimize performance, fuel efficiency, and driving comfort across various conditions.

Fluid Coupling in Automatic Transmissions

Fluid coupling is a critical component in automatic transmissions, enabling smooth power transfer between the engine and transmission. Unlike manual transmissions, which use a clutch, fluid coupling relies on transmission fluid to connect and disconnect the engine from the gears. This system allows the engine to continue running even when the vehicle is stationary, preventing stalling; The torque converter, a type of fluid coupling, multiplies torque at low speeds, improving acceleration. This hydraulic connection ensures seamless operation, making automatic transmissions ideal for city driving and providing a comfortable, effortless driving experience compared to manual transmissions.

Comparison of Manual and Automatic Transmissions

Manual transmissions use a clutch for engine disengagement, offering driver control and efficiency. Automatics rely on torque converters for smooth, hands-off power transfer, ideal for convenience and ease.

Driving Experience and Control

Manual transmissions offer a more engaging driving experience, requiring the driver to actively shift gears and use the clutch, providing a direct connection to the vehicle. Automatic transmissions, with torque converters, prioritize convenience, allowing smooth acceleration without manual intervention. The clutch system in manuals demands driver input, while automatics rely on fluid-based power transfer for seamless operation. This fundamental difference impacts both control and comfort, catering to different driving preferences and conditions.

Performance and Fuel Efficiency

Manual transmissions typically offer better fuel efficiency and performance compared to automatics. The direct mechanical connection without a torque converter reduces power loss, especially in high-performance scenarios. Automatic transmissions, while improving in efficiency, often have slightly lower fuel economy due to the torque converter’s energy absorption. However, modern automatics with lock-up converters are narrowing this gap. The lack of torque multiplication in manuals can result in more driver engagement but may require more frequent gear shifts, impacting efficiency in stop-and-go traffic. Overall, manuals remain the choice for drivers prioritizing performance and economy.

Maintenance and Cost Differences

Manual transmissions typically require less maintenance and are more cost-effective than automatics. They lack a torque converter, simplifying the system and reducing potential repair costs. Clutch replacements, though necessary, are generally cheaper than fixing or replacing a torque converter. Automatics, with their complex components like the torque converter, can be more expensive to maintain, especially if the converter fails. However, modern automatics often offer improved reliability and lower long-term maintenance costs. Manuals usually have lower upfront costs and are more fuel-efficient, making them a budget-friendly choice for many drivers.

Specialized Transmission Systems

Specialized systems like Automated Manual Transmissions (AMT) and Dual-Clutch Transmissions (DCT) combine manual control with automatic features, while lock-up torque converters enhance efficiency in modern vehicles.

Automated Manual Transmissions (AMT)

Automated Manual Transmissions (AMT) bridge the gap between manual and automatic transmissions by using an automated clutch system. Unlike traditional manuals, AMTs eliminate the need for a driver-operated clutch pedal, automating gear shifts electronically. This hybrid system improves fuel efficiency and performance while maintaining the simplicity of manual transmissions. AMTs do not use torque converters, relying instead on electronic controls to manage gear transitions. They offer a cost-effective and efficient alternative to fully automatic transmissions, though they may lack the smoothness of torque converter-based systems. AMTs are popular in regions where fuel efficiency and affordability are prioritized.

Dual-Clutch Transmissions (DCT)

Dual-Clutch Transmissions (DCT) are advanced semi-automatic systems that combine the efficiency of manual transmissions with the convenience of automatic shifting. Unlike traditional manuals, DCTs use two clutches to pre-select gears, enabling faster and smoother shifts. This design eliminates the need for a torque converter, leveraging the dual-clutch mechanism to connect and disconnect the engine from the transmission. DCTs provide quick acceleration and improved fuel efficiency, making them popular in performance vehicles. However, they can be complex and less refined in low-speed driving compared to torque converter-based automatics. Dual-clutch systems are favored in racing applications for their precise control and rapid gear changes.

Lock-Up Torque Converters in Modern Systems

Lock-up torque converters are advanced components in modern automatic transmissions that enhance efficiency and performance. Unlike traditional torque converters, lock-up models physically engage the engine and transmission, reducing slippage and improving fuel economy. This direct connection mimics the feel of a manual transmission during high-speed driving. Lock-up converters are typically used in higher gears to optimize power transfer and minimize energy loss. They are widely adopted in contemporary vehicles to balance smooth acceleration with improved mileage, addressing the limitations of earlier torque converter designs. This technology bridges the gap between automatic and manual transmissions, offering the best of both worlds.

Historical Development of Transmissions

Manual transmissions preceded automatics, with early systems using clutches. Torque converters emerged later, revolutionizing automatic transmissions for smoother power transfer without manual intervention.

Evolution of Manual Transmissions

Manual transmissions have evolved significantly since their inception, beginning with basic, non-synchronized gear systems that required double-clutching. The introduction of synchromesh in the mid-20th century made shifting smoother and more accessible. Modern manual transmissions now feature advanced materials, compact designs, and improved gear ratios for better performance and fuel efficiency. The clutch system has also seen advancements, transitioning from external linkages to hydraulic and cable-actuated systems. Despite the rise of automatics, manual transmissions remain popular for their driver engagement and control, with continuous innovations enhancing their reliability and usability.

Torque converters were first introduced in the 1940s as a key component in automatic transmissions, revolutionizing the driving experience. They replaced manual clutch systems by enabling smooth, automatic gear shifts without driver intervention. The torque converter uses fluid coupling to transfer engine power to the transmission, allowing the engine to idle independently of the wheels. This innovation eliminated the need for manual gear shifting, making cars more accessible to a broader audience. The introduction marked a significant milestone in automotive technology, enhancing convenience and performance for drivers worldwide.

Modern Advances in Transmission Technology

Modern transmission technology has introduced innovative solutions to enhance performance and efficiency. Automatic transmissions now feature lock-up torque converters, reducing fuel consumption and emissions by creating a direct mechanical connection during cruising. Dual-clutch transmissions (DCTs) combine the efficiency of manual gearboxes with the smoothness of automatics, offering rapid shifting and improved fuel economy. Automated manual transmissions (AMTs) use electronic controls to handle clutch engagement, blending manual precision with automatic convenience. These advancements cater to diverse driving preferences, ensuring optimal power delivery while minimizing environmental impact.

Performance and Racing Applications

In high-performance vehicles, manual transmissions are preferred for their direct control and faster shifting, while torque converters in automatics optimize low-end torque for rapid acceleration.

Torque Converters in High-Performance Vehicles

Torque converters play a crucial role in high-performance vehicles with automatic transmissions. They enable smooth power delivery and rapid acceleration by multiplying torque at low speeds. This feature is particularly advantageous in drag racing and scenarios requiring quick launches. However, in professional racing, manual transmissions are often preferred due to their direct control and faster shifting capabilities. Modern high-performance vehicles sometimes incorporate lock-up torque converters, which engage the engine directly to the transmission, mimicking manual transmission performance while retaining automatic convenience.

Manual Transmissions in Racing

Manual transmissions dominate racing due to their precise control and faster gear shifts. Drivers can optimize acceleration and maintain engine speed in the power band, enhancing performance; Unlike automatics, manuals avoid torque converter slippage, offering direct power transfer. This makes them ideal for competitive environments where milliseconds matter. Additionally, manual transmissions are lighter and simpler, reducing overall vehicle weight and improving handling. However, the physical and mental demands of constant shifting can be challenging, even for skilled drivers. Despite advancements in automatics, manuals remain the preferred choice in most racing categories.

Impact of Torque Converters on Acceleration

Torque converters significantly influence acceleration in automatic transmissions by allowing the engine to rev freely without engaging the wheels. This enables smooth starts from a standstill and low-speed maneuvers. The converter’s torque multiplication feature temporarily increases torque output, enhancing initial acceleration. However, during high-speed driving, the lock-up clutch engages, reducing slippage and improving efficiency. While torque converters provide seamless acceleration, they can introduce slight power loss compared to manual transmissions, which offer direct mechanical connection. This trade-off balances comfort and performance, making torque converters a key component in automatics for everyday driving scenarios.

Myths and Misconceptions

A common misconception is that manual transmissions use torque converters. This is false, as manuals rely on clutches, while torque converters are exclusive to automatics.

Do Manual Transmissions Ever Use Torque Converters?

Manual transmissions do not use torque converters. They rely on a clutch system to disconnect and connect engine power to the transmission. Torque converters are exclusive to automatic transmissions, where they facilitate smooth power transfer without manual intervention. Some niche applications, like extreme performance or specialized systems, might experiment with torque converters in manual setups, but this is highly unconventional. The fundamental design of manual transmissions revolves around the clutch, making torque converters unnecessary and impractical for their operation. This distinction underscores the unique characteristics of each transmission type, catering to different driving needs and preferences.

Is a Torque Converter Better Than a Clutch?

A torque converter and a clutch serve different purposes, making direct comparison challenging. Torque converters in automatic transmissions provide smooth, seamless power transfer and prevent engine stalling at low speeds. They eliminate the need for manual shifting, offering convenience and ease of use. Clutches in manual transmissions allow direct engine control, enabling precise gear changes and better fuel efficiency. However, clutches require driver engagement and can be less convenient in heavy traffic. While torque converters offer smoothness, clutches provide superior performance and driver connection. The choice depends on driving preferences and needs, as neither is inherently “better” universally.

Common Misunderstandings About Transmissions

One common misunderstanding is that manual transmissions use torque converters, which they do not. Torque converters are exclusive to automatics, aiding smooth power transfer without manual shifting. Another myth is that automatics are less fuel-efficient, though modern automatics often rival manuals. Some believe manuals are always faster, but high-performance automatics can outperform them. Additionally, people often think manuals require more maintenance than automatics, but both have similar needs. Understanding these distinctions helps in making informed choices based on actual performance rather than misconceptions.

Manual transmissions use a clutch, not a torque converter, to connect and disconnect engine power, while automatics rely on torque converters for smooth power transfer without manual intervention.

Final Thoughts on Manual vs. Automatic Transmissions

Manual transmissions offer driver engagement and control through a clutch system, while automatics provide convenience with torque converters. Manuals are simpler, lighter, and more fuel-efficient, appealing to enthusiasts. Automatics, with their torque converters, ensure smooth power delivery and ease of use, making them ideal for urban driving and accessibility. The choice between manual and automatic transmissions hinges on driving preferences, lifestyle, and performance needs. Both systems cater to distinct driver experiences, making each suitable for different scenarios and preferences.

The Future of Transmission Technology

Advancements in transmission technology are shifting toward hybrid and electric systems, blending manual and automatic features. Dual-clutch transmissions and lock-up torque converters are becoming more efficient. Automated manual transmissions (AMT) and continuously variable transmissions (CVT) are gaining traction for enhanced fuel efficiency. The integration of advanced materials and smart software promises lighter, more responsive systems. As electric vehicles rise, traditional transmissions may evolve into simpler, more compact units. The future likely holds seamless integration of manual control with automatic convenience, optimizing performance and efficiency across all driving conditions.